how fineness of material can very in vertical roller mill

2019-03-02T19:03:48+00:00

How do you adjust the fineness of a vertical roller mill?

Generally speaking, when vertical roller mill is working, there are three main ways to adjust the fineness They are the adjustment of the motor speed, the adjustment of the swing Summary: This method is mainly to adjust the fineness of vertical roller mill,The fineness of materials can be adjusted by adjusting the grinding pressure conditions Generally Adjust The Fineness Of Vertical Roller Mill Gravel MillProfessional Vertical Roller Mill For Waste Rock Grinding Jul 02, 2021 Guilin Hongcheng mineral powder mill HLM vertical roller mill 〖 Product fineness 〗 22180μm 〖 Production capacity How Fineness Of Material Can Very In Vertical Roller Mill

how fineness of material can very in vertical roller mill

The coal vertical roller mill has less dust, low noise, high efficiency granular composition, and excellent combustion performance due to its special design and structure As a professional manufacturer of grinding mills, Shuguang Heavy Machinery sells a variety of different types of mill equipment, including ball mills, Raymond mills, vertical mills, How to adjust discharge fineness of vertical roller mill Vertical roller mills are widely used in chemical, metallurgy, nonmetallic mining, and other industries It suitable for huge capacity producing, widely used in grinding nonflammable and Vertical Roller Mill Ultrafine Powder Technology

how fineness of material can very in vertical roller mill

Introduction to the Vertical roller mill materials enter the Vertical roller mill, fineness in vertical roller mill Description : Chat Now; Vertical roller mill use and quality advantages Another Other factors (1) Height of retaining ring The height of the retaining ring directly affects the stability of the material layer and the grinding efficiency of the vertical roller mill If Factors affect the operation and running of vertical roller mill Other factors (1) Height of retaining ring The height of the retaining ring directly affects the stability of the material layer and the grinding efficiency of the vertical roller mill If Factors affect the operation and running of vertical roller

how fineness of material can very in vertical roller mill

LM Vertical Roller Mill, Vertical Mill Manufacturer Vertical roller mill is used to pulverize materials like limestone, coal, feldspar, calcite, fluorite, talc, iron ore, copper ore, Generally speaking, when vertical roller mill is working, there are three main ways to adjust the fineness They are the adjustment of the motor speed, the adjustment of the swing position of the grinding roller, and the adjustment of the air volume of the fan First, The Adjustment Of Motor SpeedAdjust The Fineness Of Vertical Roller Mill Gravel MillFor raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our Vertical Roller Mills

Factors affect the operation and running of vertical roller mill

The hardness of the grinding material is usually characterized by Mohs hardness (range 110) Generally speaking, the higher the hardness of the material is, the worse the grindability and the higher the wear of vertical roller mill Air Volume Control The differential pressure of the vertical roller mill is generally controlled at 5000~7000Pa to ensure the proper air volume The change of the pressure difference within the mill is mainly affected by the feed amount when other conditions are constant Therefore, the feed amount should be stabilizedHow to Improve Grinding Efficiency of Vertical Roller MillFineness: 200325 mesh (7544μm) HLM series vertical grinding mill is a kind of advanced pulverizing equipment integrated with drying, pulverizing, powder selecting and conveying It is applied as a good solution to the technical issue such as low output, high energy consumption and high maintenance cost in the ordinary industryHLM Vertical Roller Mill hcmilling

Advantages of Superfine Vertical Roller Mill CLIRIK

The superfine vertical mill has the advantages of high grinding efficiency, low power consumption, large feeding particle size, easy adjustment of product fineness, simple equipment process flow, small floor area, low noise, small dust, simple operation and maintenance, low operation cost, low consumption of wearresistant materials, etc In the study, raw materials including clinker, gypsum, pozzolan were separately milled on a ball mill (the ball mill size: φ500 mm × L500 mm, productivity: 5 kg / grinding time) to achieveCements ground in the vertical roller mill fulfil The ball mill can only pulverize, and other functions need to be configured separately 3 Processing materials The vertical roller grinding mill is mainly suitable for superfine powder processing of nonflammable and explosive brittle materials with medium and low hardness and Mohs hardness less than 7How to choose between ball mill and vertical roller mill?

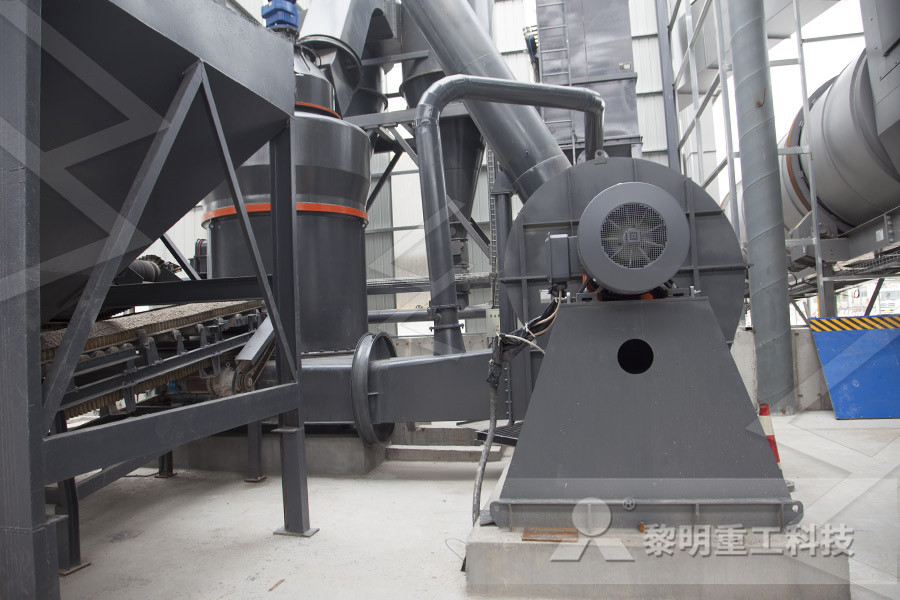

diagram of vertical roller mill

The structure of vertical roller mill The structure of vertical roller mill is various, but its principle is basically similar The roller press is mainly composed of feeding device, material position control device, a pair of sticks, rotating device (motor, pulley, gear shaft), hydraulic system, and horizontal leakage prevention device Currently, the equipment has been used on a 56m slag vertical roller mill of a building material company in Tangshan at the end of 2013 By adjusting the new type wind board reasonably, vertical mill can achieve or even surpass the design production when grind different kinds of Hlm Vertical Roller MillFineness In Vertical Roller Mill In the process of work, the speed of the main engine and the engine of the vertical mill will affect the feeding and discharging speed of the powder, and vertical roller will also have a certain impact on the quality of the grinding By controlling the engine current, the rotation speed can be very good The control to control the fineness of How to control the material fineness of vertical mill in

Fineness In Vertical Roller Mill Xpedia

How To Adjust Discharge Fineness Of Vertical Roller Mill how to adjust discharge fineness of vertical roller mill article sourceadmin popularity dateline 16:12 in the ore powder processing and manufacturing industry, vertical roller mill is a common equipment and the mainstay Grinding Fineness Of The Vertical Roller Mill Other factors (1) Height of retaining ring The height of the retaining ring directly affects the stability of the material layer and the grinding efficiency of the vertical roller mill If the height of the retaining ring is too high, this is not conducive to the overflow of the material, leading to the thickening of the material bedFactors affect the operation and running of vertical roller mill Air Volume Control The differential pressure of the vertical roller mill is generally controlled at 5000~7000Pa to ensure the proper air volume The change of the pressure difference within the mill is mainly affected by the feed amount when other conditions are constant Therefore, the feed amount should be stabilizedHow to Improve Grinding Efficiency of Vertical Roller Mill

Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill

The vertical works according to the principle of layer material to powder Low energy, the powder consumption of vertical mill is 20%30% less than that of ball mill With the incensement of moisture of the raw material, the powder consumption will decrease obviously The vertical mill saves 30%40% of energy consumption compared to the ball mill 【Product description】: Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materials 【Product capacity】: 30720 t/h 【Power】: 2530 KWh/t 【Specific surface area】: 330 Cement Vertical Roller Mill greatwallcorporation In the past, high pressure grinding rolls (HPGR), vertical roller mills (VRM) had positive effects on the overall energy utilization of cement grinding however some quality issues had also been Cements ground in the vertical roller mill fulfil

PROCESS CONTROL FOR CEMENT GRINDING IN

the mill table, due to mill and roller’s relative movement, materials get into the grinding layer between the roller and the mill In suspension between classifier and table, material drying transpires will takes place The unstable grinding bed causes the VRM to vibrate Water is directly sprayed into the bed to make dry mill feed, which isThe structure of vertical roller mill The structure of vertical roller mill is various, but its principle is basically similar The roller press is mainly composed of feeding device, material position control device, a pair of sticks, rotating device (motor, pulley, gear shaft), hydraulic system, and horizontal leakage prevention devicediagram of vertical roller millVertical roller mill: can be used in 300 kinds of different soft and hard mineral powder grinding, such as: cement, slag and other hard material, it's easy to process by vertical roller mill, and compare with Raymond mill the vertical roller mill has a fineness in vertical roller mill sebocomconstructioncoza

Factors affect the operation and running of vertical roller mill

The hardness of the grinding material is usually characterized by Mohs hardness (range 110) Generally speaking, the higher the hardness of the material is, the worse the grindability and the higher the wear of vertical roller mill Vertical roller mills are widely used in the concrete and mining fields, and are also used to process coal,lime and gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materials Capacity: 50250 t/h Motor Power: 10005000kwVertical roller mill Chaeng Vertical Roller Mill Model: CLUM Brand: Clirik Can be used in more than 300 kinds of hard minerals powder making, common powder fineness made by vertical roller mill is about 3000 mesh, and at the same time, the finial Vertical Roller Mill and Raymond Mill Difference

Vertical Cement Mill, Vertical Roller Mill Buy Cement Mill

The vertical works according to the principle of layer material to powder Low energy, the powder consumption of vertical mill is 20%30% less than that of ball mill With the incensement of moisture of the raw material, the powder consumption will decrease obviously The vertical mill saves 30%40% of energy consumption compared to the ball mill The superfine vertical mill has the advantages of high grinding efficiency, low power consumption, large feeding particle size, easy adjustment of product fineness, simple equipment process flow, small floor area, low noise, small dust, simple operation and maintenance, low operation cost, low consumption of wearresistant materials, etcAdvantages of Superfine Vertical Roller Mill CLIRIK Vertical Roller Mill Wikipedia Vertical roller mill is a type of grinder used to grind materials into extremely fine powder for use in mineral dressing processes paints pyrotechnics cements and ceramics It is an energy efficient alternative for a ball millFineness In Vertical Roller Mill Uyr5u

Roller mills: Precisely reducing particle size with greater

Roller mill tests can help determine the right roll speed ratio for your material Roll gap Controlling the roll gap (Figure 3) is critical to achieving your required final particle size This control has two components: the roll gap size and roll alignment The roller mill operator can control the particle size by widening or narrowing the Introduction of GGBS vertical roller mill GGBS vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBS) into small particlGGBS (fineness:cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing as well as to partially replacefineness in vertical roller mill elcasarmultiasistenciaesThe structure of vertical roller mill The structure of vertical roller mill is various, but its principle is basically similar The roller press is mainly composed of feeding device, material position control device, a pair of sticks, rotating device (motor, pulley, gear shaft), hydraulic system, and horizontal leakage prevention devicediagram of vertical roller mill