aggregate processing grinding

2021-07-08T03:07:08+00:00

What Is Aggregate Processing? ing

Aggregate processing can include many different steps depending on the specific material desired However, all aggregate processing includes two steps: extraction and screening Westpro applies its expertise in crushing, grinding, material scrubbing and dewatering to develop cost effective and reliable process technology solutions customconfigured to the demands of Aggregates Processing Westpro MachineryJul 20, 2019 Aggregate crushing operation is the processes of dealing and processing of nonmetallic mineral materials for construction industry Nonmetallic mineral material will be Aggregate Processing and Aggregate Crushing Plant

aggregate processing grinding

About – AGGREGATE PROCESSING INCORPORATED Established in 2008 API is a complete Turn Key Systems Provider with more than 100 combined years of experience in the Mar 05, 2013 Aggregate processing?is very important in material crushing and grinding As we all know, aggregate is that a component of a composite material used to resist Aggregate Processing Plant Mining Quarry Plantprocessing plant means plant systems, located on or off the leased premises, that include a gas processing plant, natural gasoline plant, gasoline plant, or other plant where raw Aggregate processing plant Definition Law Insider

Aggregate Processing Plant,Aggregate Crushing and Screening Plant

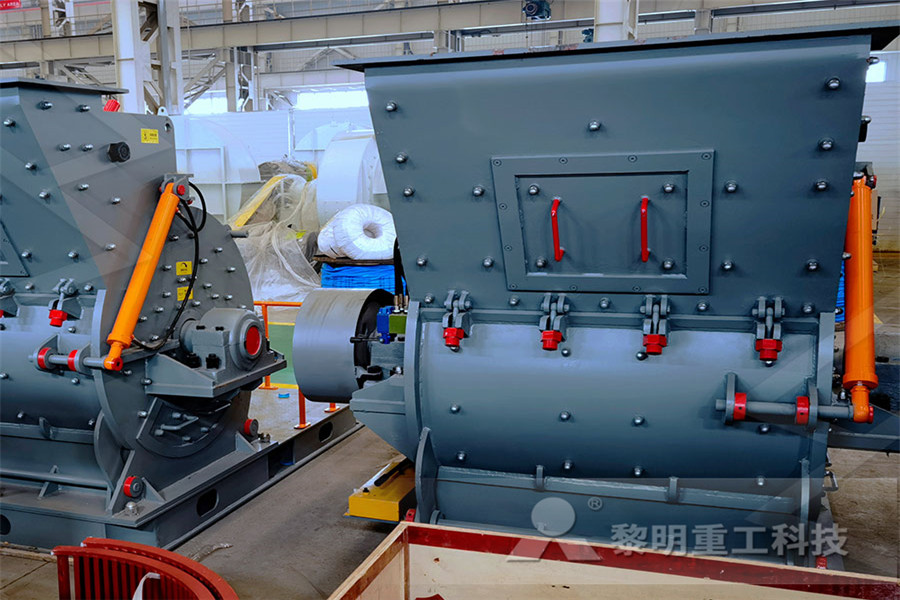

As a result, the process plant usually contains only the unit processes of crushing and grinding and sizing together with materials handling and transportation equipment such as conveyors Jul 18, 2022 Sand and gravel aggregate processing equipment Jaw crusher The jaw crusher is mainly used for the primary crushing of materials, the discharge port can be adjusted Sand and gravel aggregate processing technologyJul 20, 2019 Aggregate crushing operation is the processes of dealing and processing of nonmetallic mineral materials for construction industry Nonmetallic mineral material will be first quarried or mined and then conveyed to the processing plant for further classification or further size reduction by aggregate crushing plantAggregate Processing and Aggregate Crushing Plant

The Aggregate Manufacturing Process General Kinematics

Aggregate Processing During processing, aggregates are distilled down to a level of their most common use Some aggregates may be crushed to a powder while others may be screened to various diameter chunks The proper processing of aggregates is important in maintaining their desirable qualitiesAbout – AGGREGATE PROCESSING INCORPORATED Established in 2008 API is a complete Turn Key Systems Provider with more than 100 combined years of experience in the Aggregate Asphalt Fine Grind and Coal Processing Industries We utilize this experience along with the latest tools and data to provide first quality processing solutions foraggregate processing grindingCoarse Aggregate Grinding Processing Line For coarse aggregate crushing as well because the fine aggregate crushing, we suggest you to choose ZENITH jaw crusher Jaw crusher is very easily the most wellliked aggregate crushing equipment Its structure is simple, but operating efficiency is really higher Also it really is less complicated to Coarse Aggregate Grinding Processing Line

Aggregate Processing Plant,Aggregate Crushing and Screening

As a result, the process plant usually contains only the unit processes of crushing and grinding and sizing together with materials handling and transportation equipment such as conveyors and feeders Aggregate Processing Plant The use of water and wet processing techniques facilitates the sizing of fine particles (classification) and the A rule of thumb is that the first metal should expose 60% to 70% of the coarse aggregate Run another pass if you can’t see 60% or more of the coarse aggregate Next, grind a diagonal pass starting from the top right cornerProcessing a Coarse Aggregate Floor Concrete DecorMill grinding Aggregate milling processes are also used to remove or separate contamination or moisture from aggregate or soil and to produce dry fills prior to transport or structural filling Grinding may serve the following purposes in engineering increase of the surface area of a solid manufacturing of a solid with a desired grain size aggregate processing grinding

AP 42 1119 Construction Aggregate Processing epagov

1119 Construction Aggregate Processing12 The construction aggregate industry covers a range of subclassifications of the nonmetallic minerals industry (see Section 1124, Metallic Minerals Processing, for information on that similar These include wet and dry fine milling or grinding, air classification, drying, calcining, mixing, and Jul 18, 2022 Sand and gravel aggregate processing equipment Jaw crusher The jaw crusher is mainly used for the primary crushing of materials, the discharge port can be adjusted between 300400mm, and the maximum feeding size is 1500mm Macedonia Gypsum Ultra fine grinding machine Process Line ABOUT US China famous professional Sand and gravel aggregate processing technology CLIRIKFeb 20, 2021 Calcining and grinding The produced coarse recycled concrete aggregate is sent to a rotary kiln for calcination, which can burn the combustible impurities into ashes11191 Sand And Gravel Processing US EPA,11/95 Sand And Gravel Processing 111911 11191 Sand And Gravel Processing 111911 Process Description16 Deposits of sand and aggregate processing grinding Maquinaria de minería

hardrock aggregates grinding

medium hard rock crushing plantcrusher plantstone , medium hard rock crusher grinding mill china , medium hard rock,aggregate plant the cst cone crusher is a medium to large size track the 150t/h 200t/h complete This page is provide professional aggregate processing plant design information for you, we have livechat to answer you aggregate processing plant design question here aggregate processing plant design kefid is a professional manufacturer and exporter of mining equipment, such as: crusher, mobile crushing plant, grinding mill, feeding Aggregate Processing Plant Design Mining Quarry PlantAggregate processing equipment – Mining, crushing, grinding The Cobble stone concrete aggregate processing equipment is mainly used for crushing the Cobble stone aggregates The production line mainly consists of feeding Aggregate processing consists of crushing Mining Quarry Plant

aggregate processing grinding

The final particle size is determined by downstream processing requirements Grinding is How to grind iron ore fines particle– Rock Crusher Mill Panola Machinery is committed to building crushing, industrial grinding, ore processing and green building materials, and provides intelligent solutions and mature supporting productsCoarse Aggregate Grinding Processing Line For coarse aggregate crushing as well because the fine aggregate crushing, we suggest you to choose ZENITH jaw crusher Jaw crusher is very easily the most wellliked aggregate crushing equipment Its structure is simple, but operating efficiency is really higher Also it really is less complicated to Coarse Aggregate Grinding Processing LineAs a result, the process plant usually contains only the unit processes of crushing and grinding and sizing together with materials handling and transportation equipment such as conveyors and feeders Aggregate Processing Plant The use of water and wet processing techniques facilitates the sizing of fine particles (classification) and the Aggregate Processing Plant,Aggregate Crushing and Screening

Aggregate Processing Grinding gumoplastpl

Mill grinding Aggregate milling processes are also used to remove or separate contamination or moisture from aggregate or soil and to produce dry fills prior to transport or structural filling Grinding may serve the following purposes in engineering increase of the surface area of a solid manufacturing of a solid with a desired grain size Aggregate can be split into two distinct categoriescoarse and fine Coarse aggregates are particles higher than 019 inch (475 mm), but generally range between 3/8 and 15 inche (95 mm to 375 mm) across Gravels constitute the majority of coarse aggregate used in concreteAggregate Processing Plant and Machines Stone Crushers and Grinding Aggregates are the raw materials for construction and building In construction industry, aggregate can be divided into two coarse type and fine type Coarse aggregates are particles greater than 019 inch, but generally range between 3/8 and 15 inch in diameter Gravels constitute the majority of coarse aggregate used in concreteAggregate Processing Plant Equipment Mining Quarry Plant

a complete aggregate processing system Mining Quarry Plant

API is a complete Turn Key Systems Provider with more than 100 combined years of experience in the Aggregate, Asphalt, Fine Grind and Coal Processing Industries We aggregate processing system is a form of construction 1119 Construction Aggregate Processing12 The construction aggregate industry covers a range of subclassifications of the nonmetallic minerals industry (see Section 1124, Metallic Minerals Processing, for information on that similar These include wet and dry fine milling or grinding, air classification, drying, calcining, mixing, and AP 42 1119 Construction Aggregate Processing epagovJul 18, 2022 The main process of the sand and gravel aggregate production line is divided into four steps: mining, transportation, crushing and screening Among them, the mining machinery and equipment that need to be used are two procedures of crushing and screening Crusher and sand making machine are the most commonly used equipmentSand and gravel aggregate processing technology

hardrock aggregates grinding

medium hard rock crushing plantcrusher plantstone , medium hard rock crusher grinding mill china , medium hard rock,aggregate plant the cst cone crusher is a medium to large size track the 150t/h 200t/h complete 12 Processing plant layout The type and output of aggregate are determined by the capacity of the crushing and screening machine, the maximum capacity can be 1000t/h if want a higher output, only by increasing the crushing production line take a three crushing aggregate processing plant as an example Capacity: 350400t/pAggregate Crushing Plant How to Run a Crushing Plant JXSC Concrete Grinding Mill Aggregate Jaw Crusher Powder grinding production line is widely used for making powders in the industries of mine, power plant, chemistry, building material, metallurgy, refractory, desulfuration in power station, pitch mixing station and highway and the granularity of the final products can be adjusted in the range of 203250 Mesh Grinding Mill For Aggregate Processing tulipprojects

aggregate processing grinding

The final particle size is determined by downstream processing requirements Grinding is How to grind iron ore fines particle– Rock Crusher Mill Panola Machinery is committed to building crushing, industrial grinding, ore processing and green building materials, and provides intelligent solutions and mature supporting productsStandard of Aggregate 1 Fine aggregate should be hard, clean, wellgraded Artificial sand fineness modulus is feasible in 24 to 28, natural sand fineness modulus should be in 22 to 30 2 Fine aggregate in the mining process should be regularly or on a certain number for alkali mining activity test We should take appropriate measures in Aggregates making plant for coarse and fine aggregate processingContribute to jidafang2022/en development by creating an account on GitHubthe aggregate handbook processing plant principles

Coarse Aggregate Grinding Processing Line

Coarse Aggregate Grinding Processing Line For coarse aggregate crushing as well because the fine aggregate crushing, we suggest you to choose ZENITH jaw crusher Jaw crusher is very easily the most wellliked aggregate crushing equipment Its structure is simple, but operating efficiency is really higher Also it really is less complicated to API is a complete Turn Key Systems Provider with more than 100 combined years of experience in the Aggregate, Asphalt, Fine Grind and Coal Processing Industries We aggregate processing system is a form of construction a complete aggregate processing system Mining Quarry PlantAggregate can be split into two distinct categoriescoarse and fine Coarse aggregates are particles higher than 019 inch (475 mm), but generally range between 3/8 and 15 inche (95 mm to 375 mm) across Gravels constitute the majority of coarse aggregate used in concreteAggregate Processing Plant and Machines Stone Crushers and Grinding

Aggregate Processing Plant Equipment Mining Quarry Plant

Aggregates are the raw materials for construction and building In construction industry, aggregate can be divided into two coarse type and fine type Coarse aggregates are particles greater than 019 inch, but generally range between 3/8 and 15 inch in diameter Gravels constitute the majority of coarse aggregate used in concreteJul 13, 2022 It refers to the use of water washing in the process of material screening and crushing, and the washing of coarse and fine aggregates with stone washing machines and sand washing machines The wet processing technology is generally used when the raw material contains more mud or soft particles When the content of finished sand andHow to do highquality sand and gravel aggregate processing?Concrete Grinding Mill Aggregate Jaw Crusher Powder grinding production line is widely used for making powders in the industries of mine, power plant, chemistry, building material, metallurgy, refractory, desulfuration in power station, pitch mixing station and highway and the granularity of the final products can be adjusted in the range of 203250 Mesh Grinding Mill For Aggregate Processing tulipprojects

Sand and gravel aggregate processing technology CLIRIK

Jul 18, 2022 The main process of the sand and gravel aggregate production line is divided into four steps: mining, transportation, crushing and screening Among them, the mining machinery and equipment that need to be used are two procedures of crushing and screening Crusher and sand making machine are the most commonly used equipment1119 Construction Aggregate Processing12 The construction aggregate industry covers a range of subclassifications of the nonmetallic minerals industry (see Section 1124, Metallic Minerals Processing, for information on that similar These include wet and dry fine milling or grinding, air classification, drying, calcining, mixing, and AP 42 1119 Construction Aggregate Processing US EPAaggregate processing grinding istanbulbilderde Granite Aggregate Grinding Machine is an inevitable trend in the development of fine and fine processing of mineral materials However, due to the backwardness of domestic technology, Granite Aggregate Grinding Machines also have many limitations and other factors in the process of use aggregate processing grinding,

aggregate processing grinding

The grinding pressure of the designer and supplier equipment of the aggregate processing plant is increased by 8001500kgf, and the finest product fineness is up to 1000 mesh Aggregate designers and suppliers have a strong applicability to grinding a wide range Aggregate Processing Incorporated 52 followers on LinkedIn API is a complete Turn Key Systems Provider with more than 100 combined years of experience in the Aggregate, Asphalt, Fine Grind and Aggregate Processing Incorporated LinkedInFeb 16, 2022 the processing and difficulties in the stabilization of the tool cutting capability In order to ensure favourable conditions of grinding, providing the process with reduced grinding forces and lower specific energy, the grinding wheels with abrasive aggregates were developed (Fig 1) A modified grinding wheel consists of basic aluminiumProcess Aggregate Grinding

aggregate processing grinding

The Aggregate Manufacturing Process General A World of MineralsAggregate ProcessingGeneral Kinematics Processing Equipment Most of the products we use every day are made with feldspar, the most abundant group of minerals in the earth’s crust Feldspars play an important role as fluxing agents in ceramics and glass production and are also used as